Technology

How to Enhance Water Resistance and Abrasion Resistance: H-1002 Crosslinker

November 4, 2025

Technology

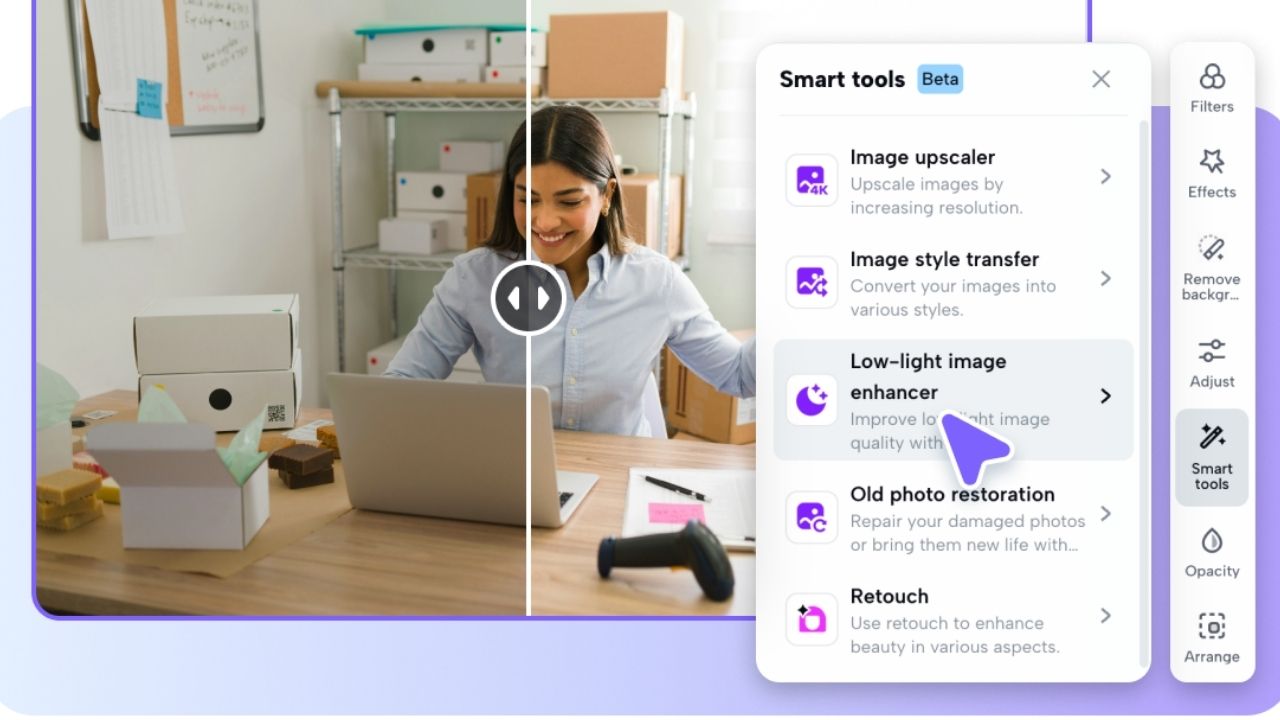

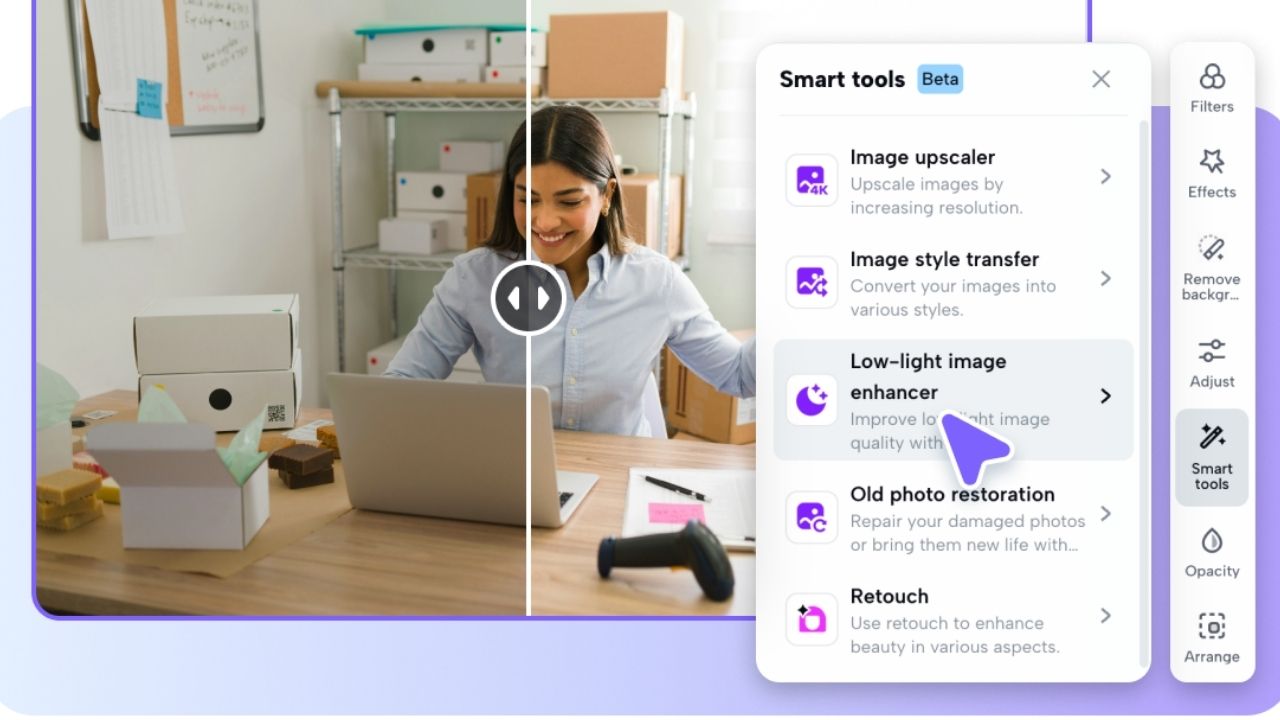

Top Uses of AI Photo Enhancers for Businesses, Creators, and Online Stores

August 19, 2025

November 4, 2025

August 19, 2025