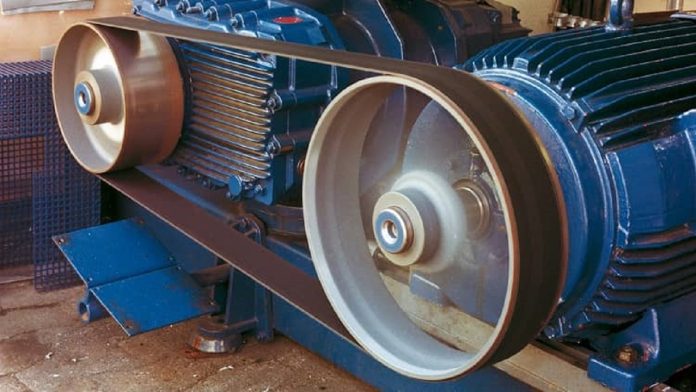

Flat belts have been used in mechanical and industrial systems for quite some time because of their outstanding simplicity of construction. Flat belts are becoming increasingly important in today’s technologies and engineered systems as technologies improve. Their characteristics, such as flexibility, low energy attenuation, and highest efficiency, make them suitable for use in different industries. This article focuses on the enhanced aspects of Flat Belts concerning their implementation in modern systems.

Energy Efficiency and Management

An important migraine consideration with flat belts is their relatively low bending loss. Small bending sections of their sub-assemblies consume little energy, making them energy efficient. Flat belts do not become wedged into grooves or pulled out of grooved pulleys, which leads to even less energy lost due to such wear. Flat belts offer the freedom of use in orthogonal setups and can work with pulleys of different sizes. These are particularly beneficial in applications where a high-speed response or standard deviation of the orientation is needed.

Durability and Longevity

These belts are designed to obtain a considerable measure of the length of existence. Since grooves do not penetrate the belt deeply, the mechanical pressure on it is minimized, and the use of the belt is increased. In the same respect, flat belts exhibit significantly lower wear rates to the pulleys, further enhancing the robustness of the system in place. It also leads to less material wear and tear and general time wastage, so flat belts are cheaper for industrial use.

Low Noise and Jerk-Free Operation

Compared to round belts, flat belts are the best types where noise is a significant issue, and minimal noise may be required. Due to their relatively low noise level, the absence of grooves makes them suitable for use in areas such as the food industry, the health sector, and office equipment, among others. The one notable characteristic of the noise levels is that a low noise environment, besides enhancing comfort, contributes positively to precise equipment.

Ease of Installation and Maintenance

Flat belts are easy to install due to their simplicity. They are easily fixed in position, and stress and consistent force reduce the chances of re-tensioning in the future. These characteristics make flat belts suitable for use where minimizing the time a system is stopped for maintenance is essential.

Application Across Industrial Sector

Flat belts have been used in manufacturing industries, agriculture, and transport. They are used in conveyors to transport material in an efficient and noiseless process. Due to their lightweight structure and low energy utilization, they are used for power transfer in automotive and aerospace. However, flat belts are increasingly adopted in renewable energy applications such as windmill operational trunks and solar tracking devices, which require higher performance.

Conclusion

The characteristics of flat belts include energy transference efficiency, power endurance, low noise consideration, and easy maintenance, which are critical in contemporary utilization. In a world where more industries are developing, flat belts are essential to effective and stable driving systems. Integrating flat belts in present-day applications increases efficiency and can be environmentally friendly and economical, making flat belts a part of future industrial evolution.